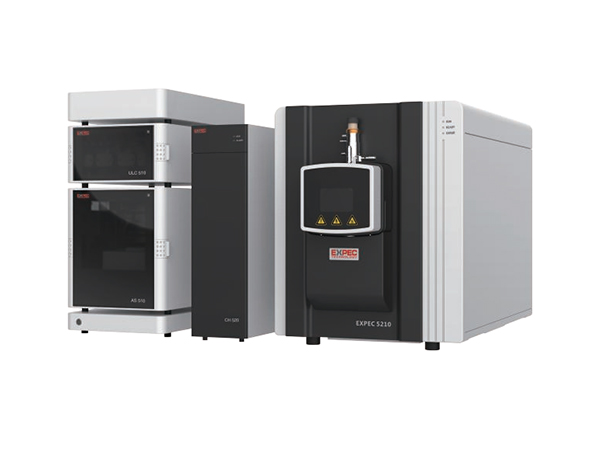

YBOTECH EXPEC-5310 liquid chromatography – triple quadrupole mass spectrometer (LC-MS), integrating the high separation efficiency of liquid chromatography and the strong identification capability of mass spectrometry, has sufficient sensitivity and selectivity, good stability and strong anti-interference. Therefore, it is applicable to the high-sensitivity qualitative and quantitative analysis of trace pesticides and veterinary drugs in complex matrix.

Feature

1) Work environment temperature: 18-25℃

2) Humidity in work environment: (20 – 60)% RH

3) Power supply: five sets of single-phase (220 ± 20) V AC, 10A, 50 Hz power supply

- Configuration and performance indicators of liquid chromatograph

1.1 Ultra-high pressure gradient pump

1.1.1 Two solutions in A and B, or C and D, can be selected as the flowing phase of the system by switching the solvent selection valve.

1.1.2 A vacuum degasser is equipped, with each pump degassing separately (A/B).

1.1.3 Flow range: 1-4,000 µL/min

1.1.4 Maximum pressure: ≥ 18,850psi

1.1.5 Accuracy of flow rate: ≤1%

1.1.6 Precision of flow rate: ≤ 0.075% RSD

1.2 Automatic sample injector

1.2.1 Three injection modes: full loop injection, partial loop injection and microliter pickup.

1.2.2 Injection repeatability: full loop injection <0.3%RSD; partial loop injection <0.3%RSD; microliter pickup<1.0%RSD

1.2.3 Cross contamination: < 0.05%

1.2.4 Maximum sample capacity: 384 bits, and 96 bits for standard liquid injection.

1.3 Column oven

1.3.1 Temperature control range: Room temperature +5℃ – 90℃

1.3.2 Temperature control mode: preheating of flowing phase + forced air circulation

2. Requirements for configuration and performance indicators of mass spectrometry system

2.1 Ion source (dual-source, i.e. ESI electrospray ion source and APCI ion source, for standard configuration)

2.1.1 Orthogonal vertical spray design is adopted, so that the system has strong anti-pollution capacity and low background noise.

2.1.2 Ion source gas supply: 1 loop of nitrogen for atomizing and 2 loops of nitrogen for desolvation. Specifically, the flow rate of nitrogen for atomizing is 0-2 L/min, and that for desolvation is 0-15 L/min. The maximum spray voltage is 6 kV. The flow rate, voltage and temperature can be set up and run under the software interface, to ensure the maximum ionization efficiency and resistance to matrix interference.

2.1.3 A special exhaust device is set in the ion source to prevent the backflow of gas in the closed ion source cavity, further to reduce the memory effect and pollution of the ion source, decrease the load of the mechanical pump, prolong the service time of the mechanical pump oil, maintain the test environment and ensure the health of the staff.

2.2 Vacuum interface and ion transmission system

2.2.1 High temperature blowback gas design: Nitrogen is used as the blowback gas, with a flow rate of 0 to 5 L/min to further remove the solvent and reduce the introduction of neutral molecules.

2.2.2 Heating design of vacuum interface: the cone hole is used for sampling to prevent capillary clogging; it can be heated to 110℃ at most to improve the anti-pollution

2.2.3 Vacuum interface maintenance: simple cleaning and maintenance, without vacuum unloading. The whole process of daily maintenance and installation can be easily completed in a few minutes.

2.2.4 Ion transmission system: 4-stage differential vacuum design is adopted, and multiple quadrupole transmission is used for accurate focusing of ions.

2.3 Mass analysis system

2.3.1 Mass analyzer: Gold-plated quadrupole made of high precision pure Mo material is used, and the material can realize the best stability through deactivation; cleanable pre- and post- quadrupoles are set to eliminate the organic deposits; and the best mass axis stability can be ensured without heating.

2.3.2 Quadrupole: Made of high-precision pure Mo material, capable of ensuring the best mass axis stability.

2.3.3 Collision cell: Hexapole axial acceleration design is adopted, capable of effectively eliminating the interference of ion pair and ensuring the high-throughput analysis capability. High-purity nitrogen is adopted as the collision gas (with the purity ≥ 99.999%), supplied in cylinders.

2.3.4 Resolution: unit resolution (full width at half maxima: 0.5 amu)

2.3.5 Mass stability: better than 0.1 amu/24 hours.

2.3.6 Scanning speed: ≥ 12,000 amu/s

2.3.7 Number of MRM channels: 100 channels/s

2.3.8 Mass number m/z scope: 5 – 2,000 amu.

2.3.9 Dynamic range: 6 orders of magnitude.

2.3.10 Sensitivity: ESI+, MRM mode: 1pg reserpine, injected on the column, with S/N≥500,000:1;

ESI-, MRM mode: 1pg chloramphenicol, injected on the column, with S/N ≥ 500,000:1;

2.3.11 Scanning functions: Full scan, selected ion monitoring (SIM), selected ion recording (SIR), product ion scan, precursor ion scan, neutral loss scan, multiple reaction monitoring (MRM), positive/negative ion switching scan, etc.

2.4 Detector

2.4.1 Multiplier technology, without any positive and negative ion discrimination effect, which has long service life, capable of ensuring the long-term data stability.

2.4.2 Pulse-counting detector, to ensure the data reproducibility of low limit of detection.

2.4.3 Positive/negative polarity switching time: ≤ 50 ms

2.5 Vacuum system: composed of a mechanical pump and a turbo molecular pump, with a differential pumping system formed between the ion transmission area and mass analysis area, functioning for automatic power-off protection.

2.6 Workstation software:

2.6.1 Basic features of software system: Windows XP or later operation platforms. The software can control the liquid chromatography and mass spectrometry, with built-in data processing and report editing functions; besides, the software can realize the function configuration and condition optimization of the instrument automatically, the automatic quantification, the mass spectrometry data analysis, and the establishment and retrieval of spectral database.

2.6.2 The system has the functions of automatic correction and instrument condition monitoring.

2.6.3 The LC-MS operation software can be installed on the personal computer, and used for the offline processing of sample analysis data and report generation.

2.7 In later stages, LCMSMS can be upgraded to be the gas phase-liquid phase-triple quadrupole mass spectrometer.

Request for quotation

Product Center

- Laboratory Centrifuge

- Spectrophotometer

- Laboratory Balance

- Water Quality Analysis

- Lab Printer

- Incubator & Oven

- Life Science Instrument

- Autoclave/Sterilizer

- Refrigerator & Freezer

- Regular Desktop Instruments

- Grinders & Mills

- Freeze Dryer

- Organic Element Analysis

- Spectrum/Chromatography

- Water Purification System

- PRP & PRF